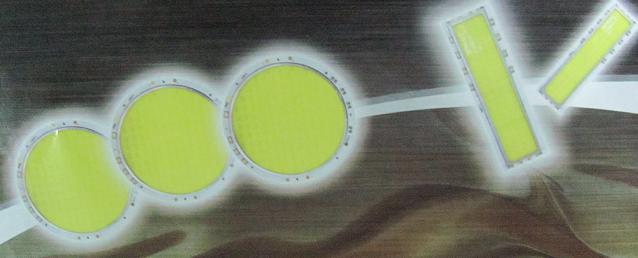

Integrated high power LED light source module surface mixed phosphor special silicone G3850A / B Manual

I. Features:

1, the product, A, B component packaging, are colorless and transparent liquid, dark environment can be saved due date. Silicon - oxygen (Si-O) bond-based chain structure, and therefore can not easily be decomposed by UV light and ozone. Unparalleled key exists, at a high temperature (or radiation) molecular bond is not broken, at -. 50 ℃ ~ 200 ℃ within the range switch to long-term use. After seven days of 300 ℃ to strengthen the gel does not crack after the test, do not harden.

3, gel was colorless and transparent gel after curing the body, the 260 ℃ reflow, the PPA and the metal has a certain adhesion.

4, has excellent electrical insulation properties and good sealing.

5, suitable for automatic or manual dispensing production SMD, fluorescent plastic;

High-power LED light source module surface mixed phosphor-specific silica gel;

Second, the recommended process: different packaging process, it is recommended to use a different ratio, it will get better results.

1, by weight ratio of A: B = 1:1 ratio with glue and stir for 10 minutes.

2, vacuum deaeration for 20 minutes.

3, in the plastic injection before, please stand at 150 ℃ than 60 minutes warm-up wave. Stents did not re-absorb moisture as soon as possible before sealing glue.

4, the first 110 ℃ bake for 1 hour, then heated to 150 ℃ bake 1 hour, sub-effective solution to the bubble problem can be cured to improve yield.

Third, note

Production should be calculated with a good amount of glue to be in operation within the plastic used. Must be evenly mixed with glue, otherwise it will not completely cure affect product performance. This product is silicone rubber products, the use of the process and what substances should be taken to avoid contact with:

1, organic tin compounds and other organic metal compounds.

2, containing organic tin compounds silicone rubber.

3, sulfur, and more sulfur compounds, polysulfones and other sulfur-containing materials.

4, amine, urethane or other amine-containing materials.

5, unsaturated hydrocarbon plasticizers.

Fourth, the technical parameters

UNCURED

Appearance

A component

Part B

Colorless liquid

Colorless liquid

Viscosity (CPS)

A component

Part B

30000

10000

Mixed Viscosity (cps)

25000

Density (g/cm3)

A component

Part B

1.05

1.00

Mixing ratio

A: B = 1:1

Allows the operating time (minutes, 25 ℃)

≥ 180

Curing conditions

110 ℃ X1 hours, then 150 ℃ X1 hours

CURED

After the appearance of sulfide

Colorless and transparent gel

Hardness (shore A, 25 ℃)

45

Refractive index (633nm)

1.420

Transmittance (450nm)

97%

Shear adhesive strength (PPA, kg/nm2)

0.25

Volume resistivity (Ω.cm)

1.0X1014

Dielectric constant (1.2MHz)

3.0

Dielectric loss tangent (1.2MHz)

1X10-3

Breakdown voltage (KVmm)

25" xd=">25">> 25